|

Electric permanent magnet chuck for guide rail

Collect

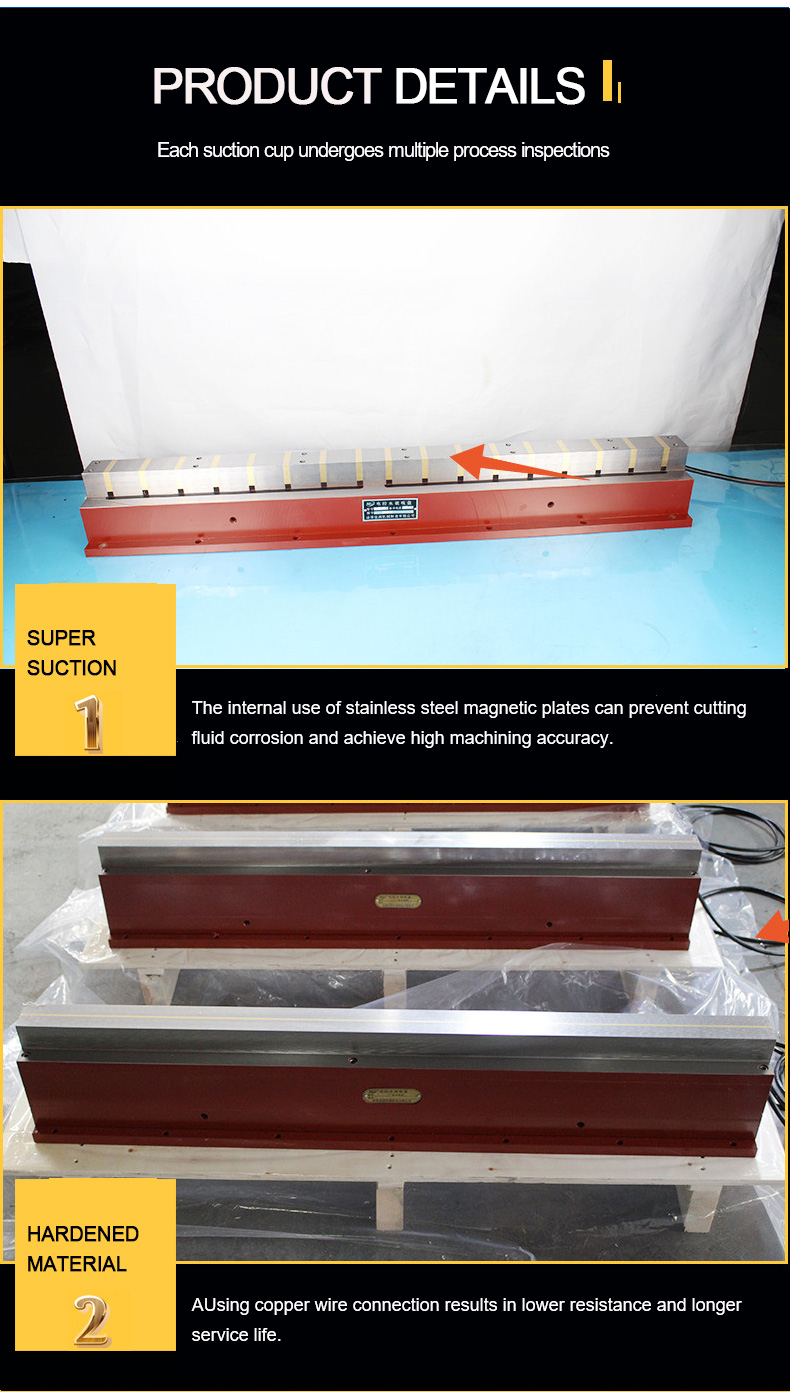

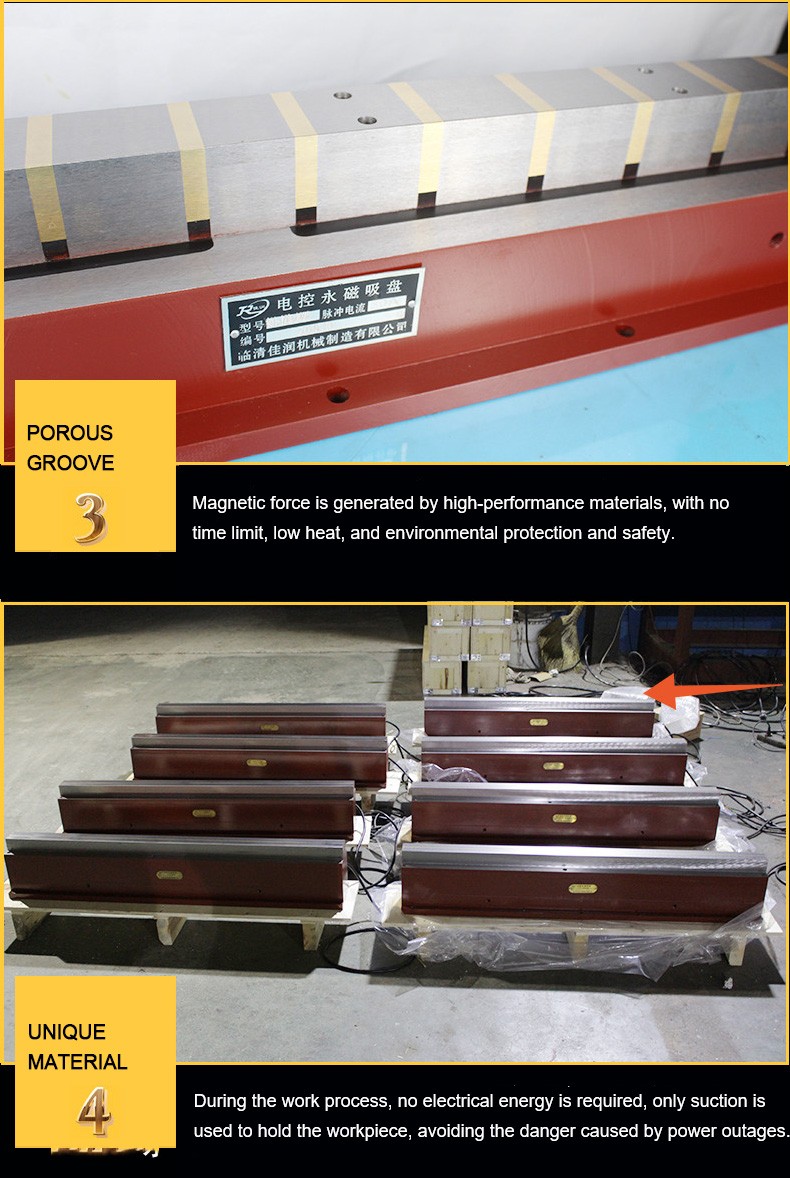

Product Introduction Suitable for single and double track linear guide grinding machines, it takes 2 seconds to charge and demagnetize, increasing work efficiency and preventing the loss of suction force due to instantaneous power outage, which will not cause damage to the workpiece or injury to workers, increasing safety. Due to the lack of power load, the suction force can be immediately cut off after magnetization, and can be maintained for a long time. Therefore, it is energy-saving, does not generate heat, has no internal temperature rise, is not easy to deform, has high accuracy, and does not need to frequently repair the disk surface, increasing disk life. The panel and magnetic block are treated with multiple waterproof layers to increase panel strength and waterproofness. The suction cup size is designed reasonably, with strong size standardization, and can achieve the length of various devices.

Specification and model Residual magnetism: ≤ 5% of the suction force at that point. Suction force: ≥ 180N/cm2

Application It can be widely used for high-precision grinding, cutting and other precision machining of various machine tools such as surface grinders, CNC milling machines, machining centers, etc.

|

||||||||||||||||||||||||||||||||||||||||