|

Automatic pressure-maintaining vacuum chuck

Collect

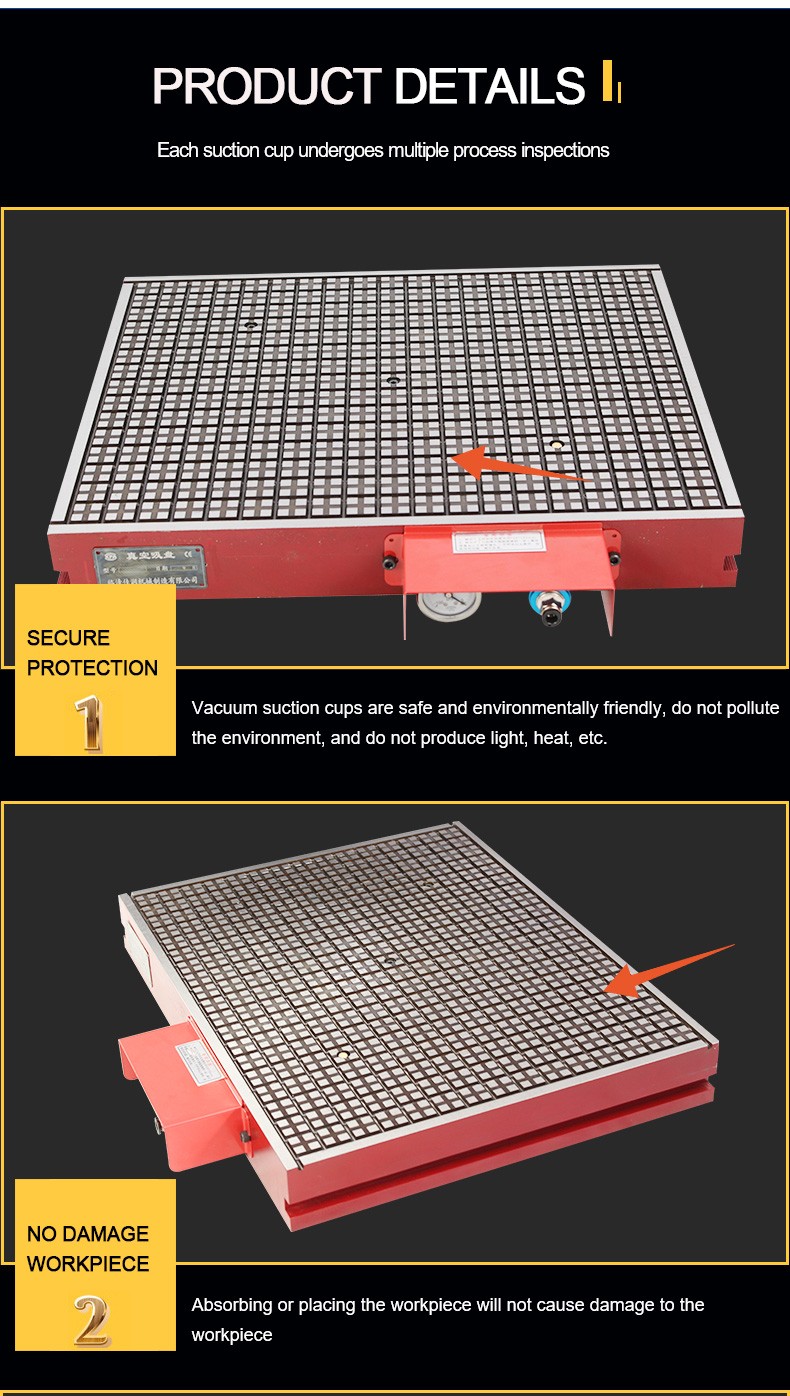

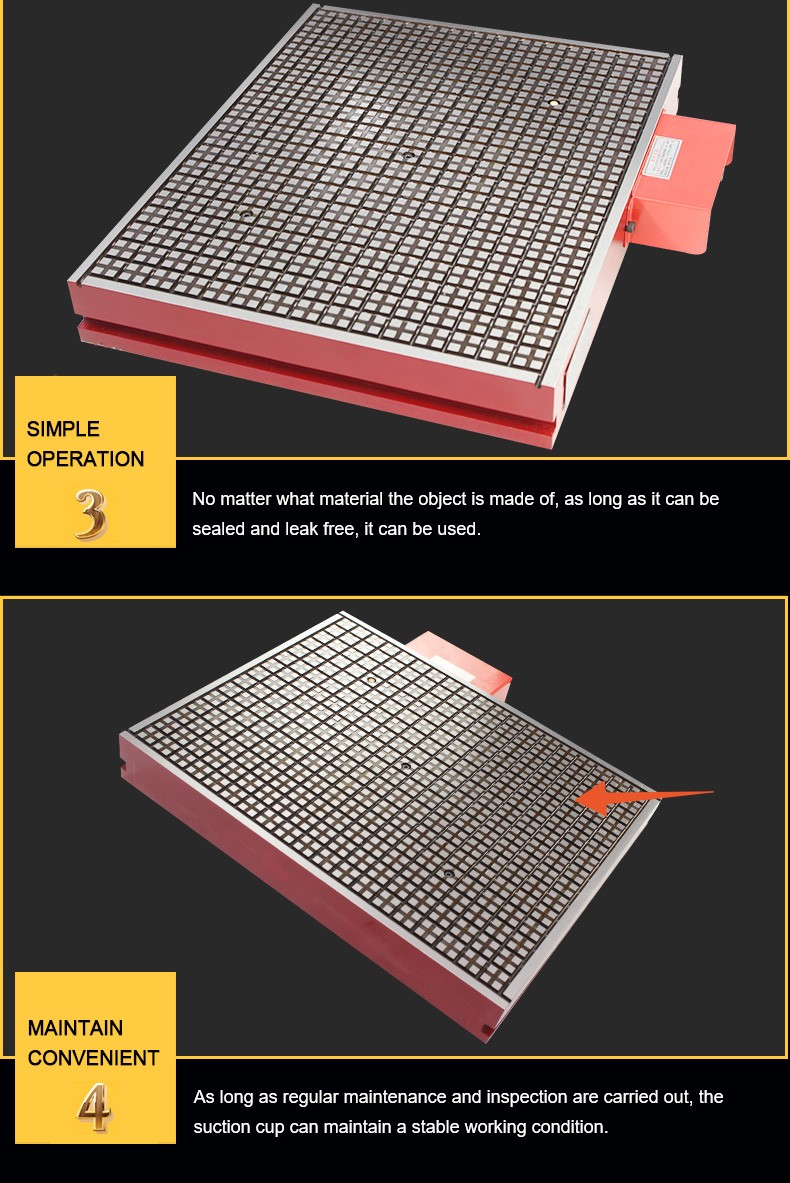

Product Introduction The automatic pressure maintaining vacuum suction cup can achieve sufficient suction force with only 6 seconds of gas supply, and there is no need for continuous gas supply afterwards. It automatically maintains pressure, saves energy and energy, has stable adsorption, and can easily solve the complex and inefficient clamping process of non-magnetic workpieces such as electric wood, acrylic, aluminum, copper plate, stone black, glass, stainless steel, etc. on the working mother machine. It can quickly perform milling, grinding and other processing of non-magnetic flat bodies. With a gentle suction, the tool can run freely, which is energy-saving, environmentally friendly and has stable performance. The pinhole vacuum suction cup can complete the processing of thin plates within 2mm, regardless of the material of the workpiece. The suction cup has high precision in the plane and does not deform when adsorbing workpieces, with even suction force.

Application Suitable for CNC machining centers, it easily solves the complex and inefficient clamping process of non-magnetic workpieces such as electric wood, acrylic, aluminum, copper plate, stone black, glass, stainless steel, etc. on the working mother machine.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||